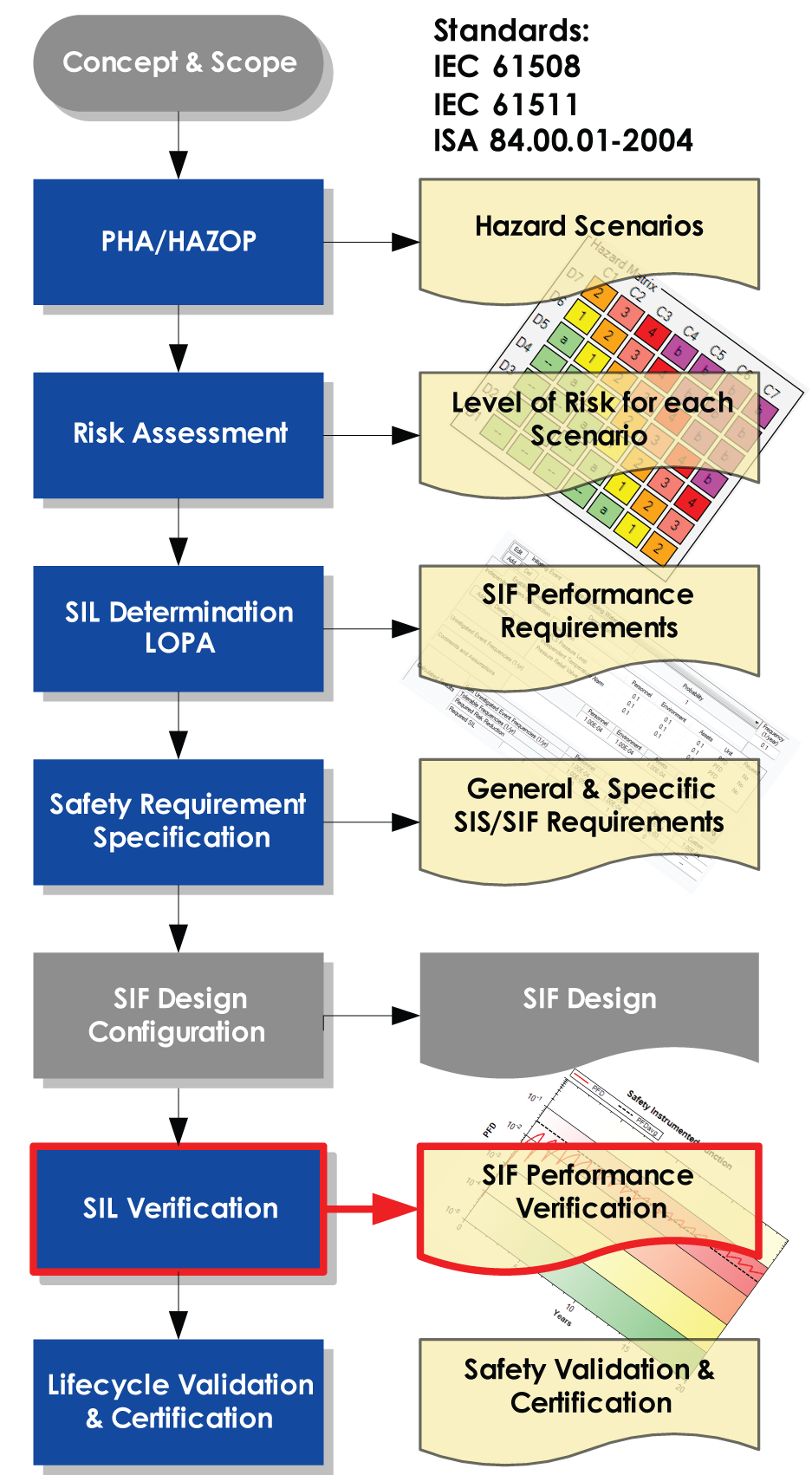

After the safety system has been designed and each safety function configured, but before any safety functions are implemented, the performance requirements of each safety function must be verified against the requirements as documented in the Safety Requirement Specification.

After the safety system has been designed and each safety function configured, but before any safety functions are implemented, the performance requirements of each safety function must be verified against the requirements as documented in the Safety Requirement Specification.

For process safety applications this involves splitting a safety function into three subsystems – the sensor subsystem, the logic solver subsystem, and the final element subsystem. Each subsystem is then evaluated using the undetected failure mode and failure rate data for the subsystem components, the proof test interval, the diagnostic coverage factor, and the common cause (Beta) factor (if required). What results is a value for the average probability of a dangerous failure (PFDavg) which is directly related to the Safety Integrity Level (SIL); and the determination whether the architectural constraints for a particular SIL have been met, based on the hardware fault tolerance (redundancy) and safe failure fraction (diagnostic coverage).

FSE Global consultants have the necessary experience to take what is a relatively complex process and use certified safety performance modelling tools to provide an independent probabilistic safety and reliability analysis of each safety function; and deliver a comprehensive report detailing every aspect of the analysis.