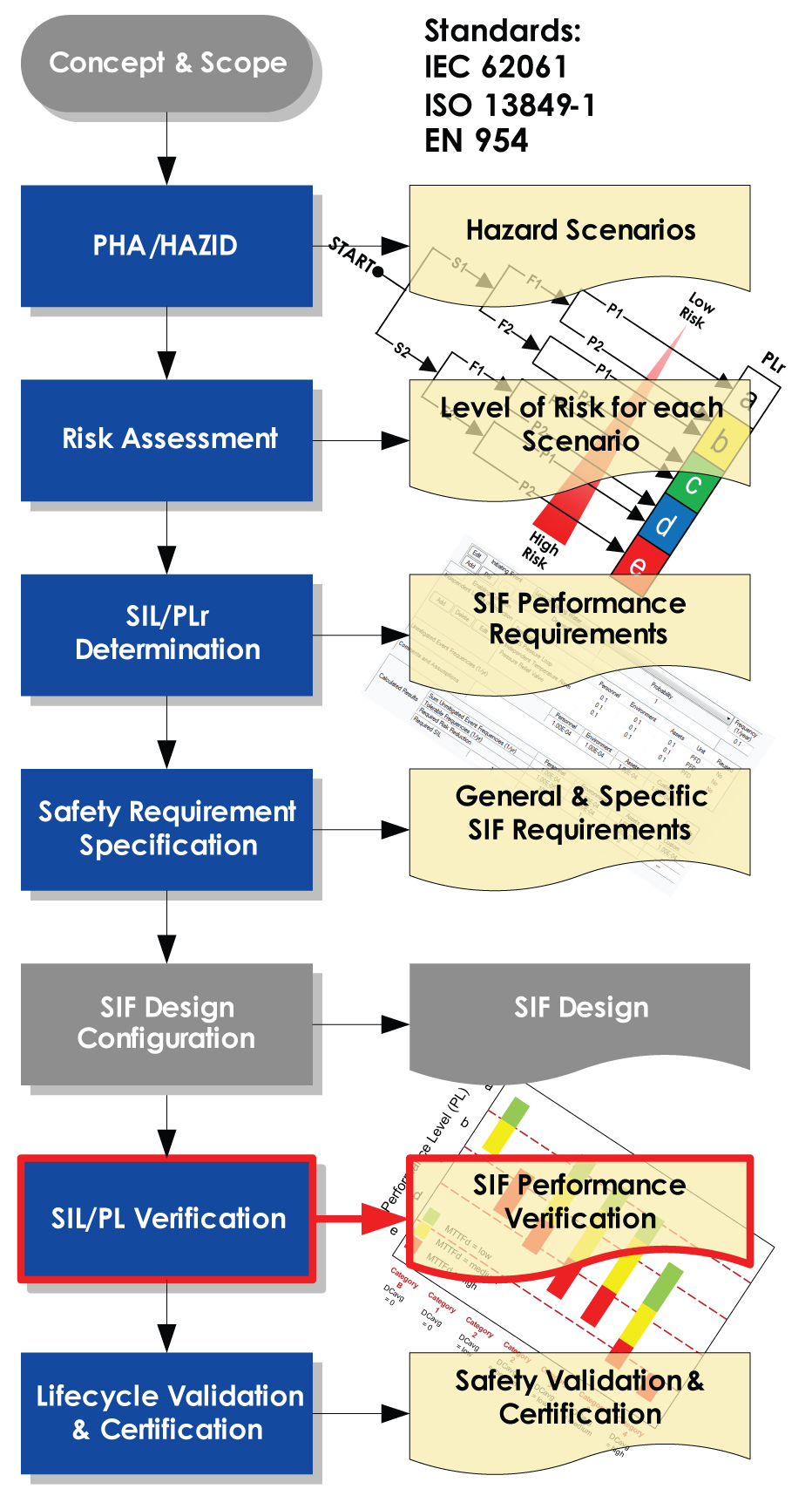

After the safety system has been designed and each safety function configured, but before any safety functions are implemented, the performance requirements of each safety function must be verified against the requirements as documented in the Safety Requirement Specification.

After the safety system has been designed and each safety function configured, but before any safety functions are implemented, the performance requirements of each safety function must be verified against the requirements as documented in the Safety Requirement Specification.

For machine safety applications complying with ISO13849-1, this involves a process of breaking a function into subsystems and component parts, and using component failure mode and failure rate data to calculate the Mean Time To a Dangerous Failure (MTTFd) of the function. After selecting a designated category of safety function, the MTTFd together with the diagnostic coverage factor (DC) and the common cause factor (CCF) are used to determine the Performance Level (PL) of the function.

For machine safety applications complying with IEC62061, this also involves a similar process of breaking a function into subsystems and component parts, and using component failure mode and failure rate data to calculate the Average Probability of a Dangerous Failure in Hours (PFHdavg) of the function. Knowing the PFHdavg, the diagnostic coverage factor (DC) and the common cause factor (Beta), the Safety Integrity Level (SIL) of the function can be determined.

FSE Global consultants have the necessary experience to take what is a relatively complex process and use certified safety performance modelling tools to provide an independent probabilistic safety and reliability analysis of each safety function; and deliver a comprehensive report detailing every aspect of the analysis.