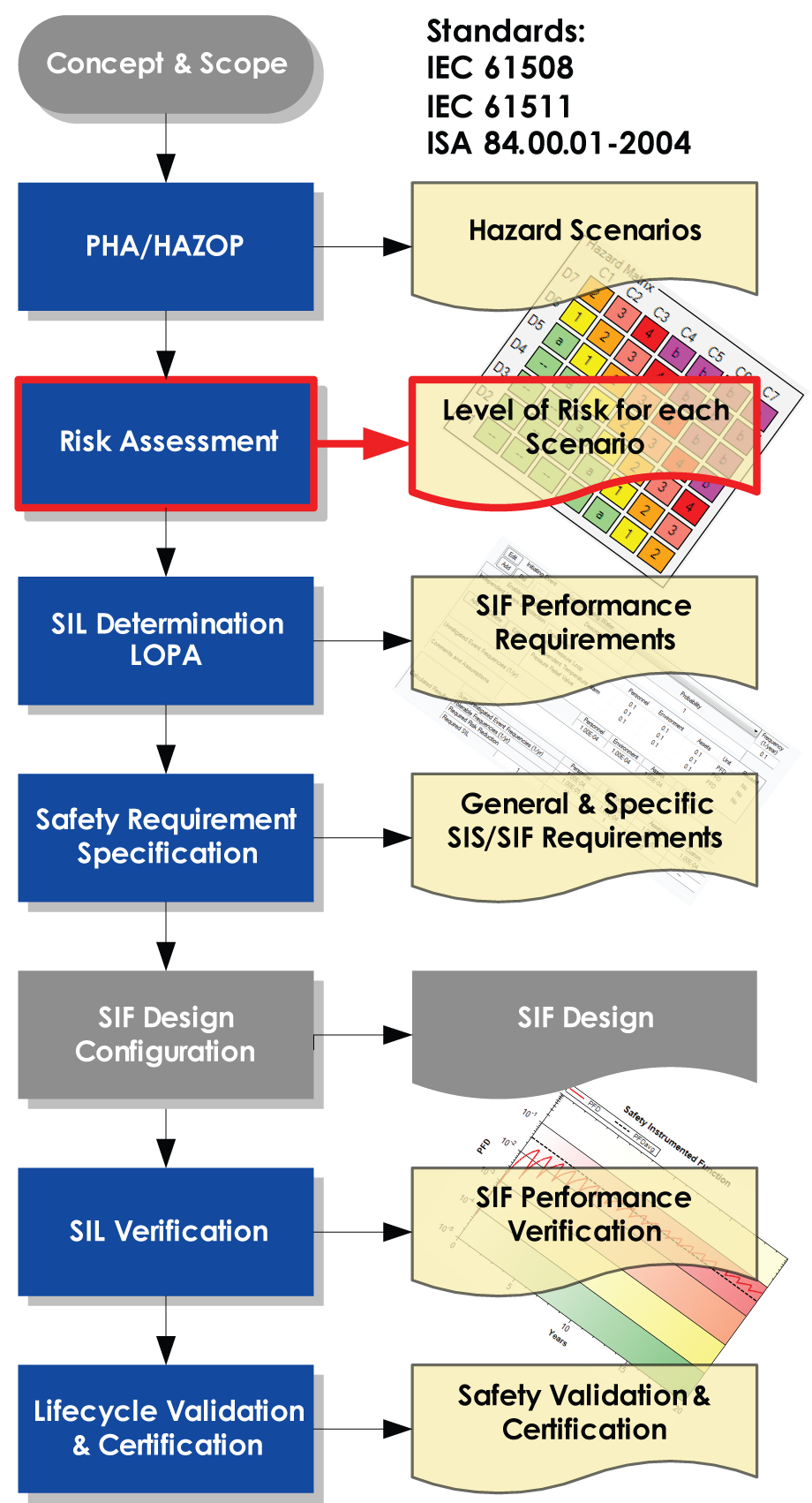

The inherent risk associated with each potential hazard scenario is typically identified as part of the PHA/HAZOP activity. Regardless of whether it is a process safety or machine safety application, it is assessed on the potential consequences and the likelihood of the event, and the existing safeguards identified during the PHA are assessed for their risk reduction capability. The residual risk, accounting for the existing safeguards, is then compared to a defined tolerable risk to determine if further risk reduction is required.

The inherent risk associated with each potential hazard scenario is typically identified as part of the PHA/HAZOP activity. Regardless of whether it is a process safety or machine safety application, it is assessed on the potential consequences and the likelihood of the event, and the existing safeguards identified during the PHA are assessed for their risk reduction capability. The residual risk, accounting for the existing safeguards, is then compared to a defined tolerable risk to determine if further risk reduction is required.

This risk assessment process is qualitative and is typically based on a calibrated risk matrix or risk graph, and serves to screen out hazard scenarios where existing safeguards have already reduced risk to a tolerable level. Where risk reduction using existing safeguards is insufficient for a hazard scenario, the scenario will be passed through to the next activity, SIL Determination, to determine their risk reduction requirements.

The tolerable risk level is determined by the Client and is often expressed by a combination of a risk matrix or risk graph together with a rule set that states the required actions for each level of risk; or as a tolerable risk frequency.

FSE Global consultants bring years of experience to the risk assessment process to ensure that it is documented accurately, and thereby avoid over-estimation or under-estimation of risk.