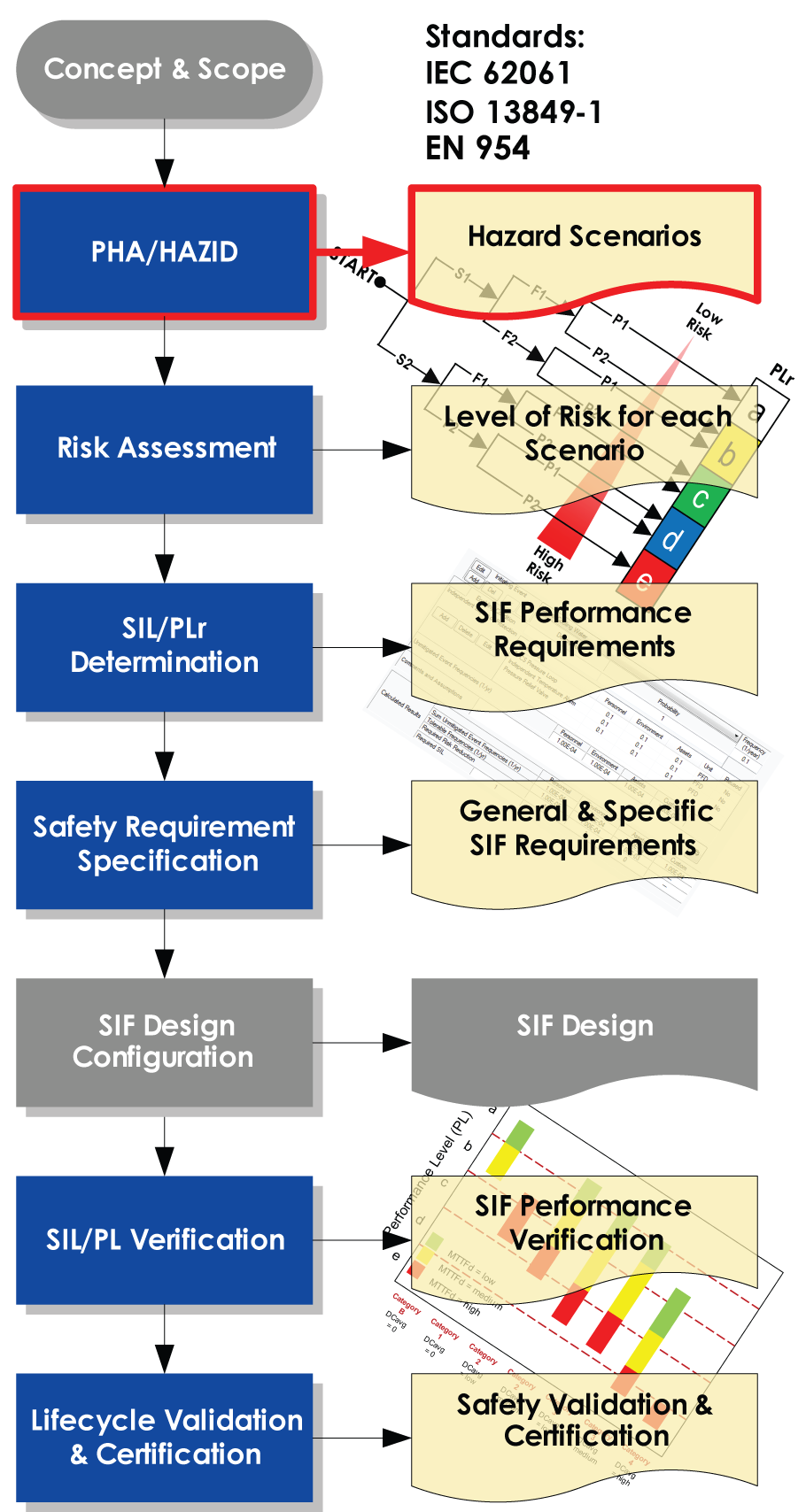

The PHA/HAZID is the start of the risk management process and the quality of the results cascades throughout the remaining safety analysis activities. It is a key activity that determines whether hazards are identified or not. This is an activity that must not be compromised – it takes experienced facilitators and a motivated, site experienced team to get quality results.

The PHA/HAZID is the start of the risk management process and the quality of the results cascades throughout the remaining safety analysis activities. It is a key activity that determines whether hazards are identified or not. This is an activity that must not be compromised – it takes experienced facilitators and a motivated, site experienced team to get quality results.

Typically, for an automation plant, the PHA/HAZID process starts by splitting a plant into machines and the tasks carried out on each machine. Each task then examined in detail for associated hazards using checklists or what-if analysis.

It pays to remember that the PHA/HAZID report is a living document; one that will be reviewed time and again over the life of the facility. If the PHA/HAZID analysis is rushed, or the results of the PHA are not recorded adequately then safety could be compromised.

FSE Global consultants facilitate PHA/HAZID workshops in a way that ensures the best possible results that are useful in the long term; and deliver a comprehensive report detailing every aspect of the workshop.